What is HACCP?

HACCP stands for Hazard Analysis and Critical Control Point systems. It is a management tool used to protect food in the food supply against biological, chemical and physical hazards. It concentrates on points in the food production process that are critical to the safety of the product being produced. It is part of USDA-FSIS regulations and requires members of the food industry to develop and implement HACCP plans and for regulatory agencies to facilitate this process (http://www.access.gpo.gov/nara/cfr/waisidx_06/9cfr417_06.html). While you are operating as “exempt” under USDA-FSIS rules, MDA still requires you to have a HACCP plan.

Every HACCP plan should be implemented using the following seven steps:

- Conduct hazard analysis and identify preventive measures.

- Identify critical control points (CCPs) in the process.

- Establish critical limits.

- Monitor each CCP.

- Establish corrective actions.

- Establish verification procedures.

- Establish record-keeping and documentation procedures.

Conduct hazard analysis and identify preventive measures.

The first step is to describe the product that you are producing and develop a flow chart of how the product is processed. In the product description include the following:

- Common name (e.g. chicken)

- How it is to be used (e.g. ready to cook carcasses)

- Type of packaging used (e.g. vacuum packed individually)

- Shelf life, at what temperature (e.g. 3-6 months at 0o F or below, 7 days at 40o F)

- Where it will be sold (e.g. on farm, at farmers’ market)

- Labeling instructions (e.g. safe food handling labels, keep refrigerated or keep frozen, cooking label, MDA-FQAP number)

- Special distribution control (e.g. keep refrigerated at 40o F or less, keep frozen).

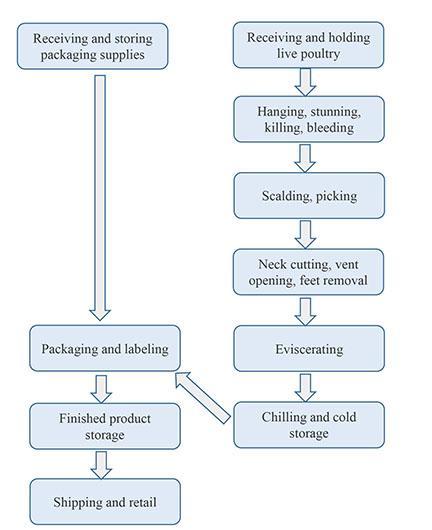

Next, make a flow chart for the product you described.

Identify critical control points (CCPs) in the process.

Now, using the flow chart, identify each point along the production process where food safety hazard are likely to occur. Make a list of these points - they are your critical control points (CCPs).

Establish critical limits.

Establish limits for each CCP that prevent or reduce contamination of the food. For example: chickens that weigh less than 4 lbs. must be chilled to 40o F or less within 4 hours.

Monitor each CCP.

Monitor the CCPs to make sure that food is produced in a safe manner. Keep records of your monitoring activity. For example: A chiller log can be maintained to verify that the carcasses are chilled properly.

Establish corrective actions

Write down what you are going to do if a critical control is not met. This will insure that the meat is safe for customers to consume. Example: Chickens that weigh 4 lbs. or less and are not chilled to 40ºF within 4 hours will be discarded and not sold for human consumption.

Establish verification procedures.

Verification is important as it ensures that the HACCP plan is followed. An example is as simple as: Employees record the temperature, time, and sign or initial the chiller log every time that they check the temperature.

Establish record-keeping and documentation procedures.

As part of the regulations requirements, you will have to maintain certain documents. These documents include:

- A written copy of the HACCP plan along with the hazard analysis. Make sure to sign and date the plan upon initial completion and any time it is modified.

- Records that show documentation of monitoring the CCPs. The chiller log would be an example of this.

- Corrective action log.

- Other records would include:

- Dates of slaughter and the number of animals slaughtered.

- Number of sick animal segregated from the healthy ones.

- If selling products to a restaurant or retailer, you must keep a copy of the invoice with date of delivery, your name and address, buyer’s name and address, identity and quantity of product.

- If selling directly to consumer from farm or at farmers’ market, you must keep a record that includes date of sale, number sold, and location of sale.

Final thoughts.

Remember to keep things as simple as possible. When things get complicated they are less likely to be followed. This plan is designed to help you produce a safe product, but it is only effective if it is followed. If you do not slaughter animals every day, do not use the word “daily” in your plan. Instead, say that you will monitor on days when animals are processed and when product is being stored.